|

WICKS TO FIT THE HEATERS LISTED BELOW - AND MORE!

Unique Specialty wicks

|

World's Largest Selection of Wicks!

Frequently Asked Questions = HEATERS For Frequently Asked Questions on LAMPS, click here (This page is a work in progress and the subjects are not in any specific order.)

1. Red Dye Kerosene Question. "There appears to be some confusion about using red dyed K1 in wick-type heaters. I have two Sengoku heaters and two Aladdin lamps which I use every winter and have always used clear K1. The clear K1 is no longer easily available in my area so I am considering switching to red K1. Some say the red dye will clog the wicks, others say there will be no problem. What is the REAL truth about this and have tests been done? Just bought a HMN-110 (w/ OS-65B wick) and the instructions say use either clear or red. Your take on this?" Al L. Answer: The red dye can

cover many sins of adultered kerosene. All product warning labels

must be written by product liability lawyers because there is no

shortage of Darwin Award Candidates in this world. Most red dye

kerosene is pretty good except for the dye itself. The HMN-110

has a very tall catalytic converter burner unit and can burn good

red dye kerosene without an aroma. Other radiant heaters in this

class include the Corona SX-2e and the Aladdin TR2000 & TR3000.

Many older heaters were made to burn Japanese kerosene cleanly,

but Japanese kerosene is more refined than American 1K clear

kerosene, and they struggled to even burn clear kerosene without

an aroma: an example would be the KeroSun Radiant 8 heater. 2. California Kerosene Question. I am noticing that the heater in my garage doesn't feel that great unless you are very close to it, I have it adjusted just right, nice blue flame, it just doesn't seem to heat well, I wonder if it's because it's a shorter model at 17" high as opposed to the taller 21" high models. What do you think. And thanks for all the work and an informative website, it's fantastic. Regards Richard Answer. Kalifornia kerosene has a flashpoint of 170 F. Traditional kerosene has a flashpoint of 104 to 107 F. There simply isn't as much heat produced per gallon as there used to be. Sunnyside brand kerosene is still sold in some Ace Hardware stores and a few other outlets in California that seems to have escaped the notice of the bureaucrats in Sacramento and does work well in heaters. Some red dye kerosene is also very good, though red dye kerosene can be a problem in some flame spreader heaters like your Aladdin Blue Flame. The only solution I know of is to try various brands of kerosene until you find one that works better in your heater. That would be less expensive than moving to a State that does not want to protect you from yourself in Big Brother fashion. ~~~~~~~~~ 3. Perfection-type heater burning poorly Question: Good evening. I have a Sears M 155.70011 kerosene heater that I just cannot seem to get running properly. I received it some time ago, and it was quite rusty. It had also been painted with paint not suitable for high temperatures. I sanded everything, repainted it with high-temp paint, and cleaned all of the parts to the burner assembly. I installed a model 500 wick that I ordered from you, but I just cannot seem to get the heater running properly. It constantly smokes. It will set off the fire alarm within minutes of bringing it into the house. Is there anything that I could possibly do in to get this burning properly? Answer: Flame spreader designs

like your Perfection clone have three critical factors: Good fuel, good

wick and a good airflow. I am assuming you are burning 1K clear kerosene

and you have a good wick. That leaves airflow because without a proper

mixing of air with the fuel the result is incomplete combustion and

smoke and smells. The usual culprit is the airflow to the inside surface

of the wick. 3A. Perfection heater wicks, 3 or 4 "tails." Question: "See the attached pics showing that the tail of the wick should be cut into 4 sections." Answer: The wicks were made by different

manufacturers but for the same heaters. The wick on the left in your

photo with four tails was made by Hattersley. Hattersley Perfection 500

wicks are no longer available. The wick on the right was made in Korea,

currently the only manufacturer of Perfection 500 wicks. ~~~~~~~~ 4. Radiant 10 Manual Question: Toyotomi's website shows a manual for K, L, and M but not for H, I, J. or a through J. Will the one available work? Answer: KeroSun had new model

numbers for virtually unchanged heaters. Often only the wick was

changed. One model would have 2 tails, the next 3 tails, then 4, and

back to 2 tails again. Same wick! But each model number often had its

own wick number. The idea was to generate a revenue flow to the dealers

after the heaters were sold as nobody else could figure out their model

numbers. It got so complicated that it was a contributing factor to

KeroSun going bankrupt and Toyotomi to begin selling the same heaters

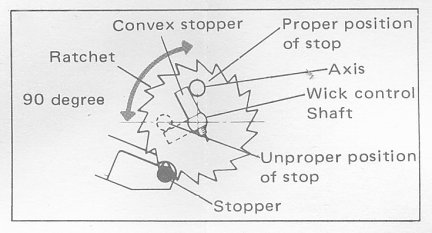

under the Toyoset and Toyostove labels. ~~~~~~~~~ 5. HMN-110, wick #4E. Question: I noticed the wick has resistance when turning it off it doesn't seem to be as smooth as the original as far a sliding down. Answer: The wick has to be really pressed into the barbs on the wick sleeve. The CTN-110 was copied from the Corona SX-2e, but it had clips to hold the wick in place. The SX-2e was copied from the Aladdin TR2000 which had holes in the wicks for brackets to hold the wick in place. Those were needed because the single lever design of the heater meant the wick was slammed down and had a tendency to slip. The CTN-110 uses a conventional wick but with a thick inner cloth band to grab the barbs to hold it securely in place, so the wick must be pressed into the barbs. If the wick is not impaled on the barbs then the effect is for the wick to be too thick, which makes it more difficult to move AND the compression effects the capillary action of the wick. To make it easy to do, put the wick in the wick sleeve so the installation line is just above the top of the wick sleeve, then with the wick sleeve in the riser mechanism turn it upside down and lower the wick over the center draft post. Gently press the wick into the hollow air draft pillar all around to push the sharp barbs into the wick. Then lift it off, turn right side up, and install normally. ~~~~~~~~~ 6. Breathe Easy Catalytic Filter Question: Hey Miles, question about the "Breathe Easy" Platinum Catalytic Filter. How long do they last? I'm assuming it's a simple oxidation catalyst that uses the platinum to turn CO into CO2 and steam. As such, no part of the screen is consumed by the reaction - so it's not really a filter, but a true catalytic converter. With proper care they should last indefinitely? Am I on the right track here? Answer: I do not know how long the Breathe Easy lasts as I have only tested them for about 8 years. Your assumption is correct about the screen not being consumed by the reaction, but it is a relatively fine screen and does act as a filter to trap large soot particles if someone adjusts their wick entirely incorrectly. Lasting indefinitely would be dependent upon the quality and thickness of the platinum coating. I have no way of measuring the thickness of the platinum but it cannot be too thick or we could not afford them. Platinum can also be brittle and break off the underlying metal mesh if bent or flexed significantly. I have no way of determining if that could occur when used by someone else. NOTE: THE BREATHE EASY CATALYTIC FILTER IS NO LONGER AVAILABLE. I sold them all. ~~~~~~~~~ 7. Spring tension on wick knob fouled up. Question: The knob now won't freely adjust the burner. It's locking on the emergency latch and it won't let me turn it CCW unless I hold down the latch. I can turn CW which is loading up the spring. Answer:

Hold the wick knob and release the escapement lever ("stopper" in illustration above) by pulling it down. Then let the knob slip in your hand when you slightly release grip pressure. When the spring is completely unsprung, turn it two turns to the right, engage the escapement lever, hold the lever with your left hand, and crank the wick knob up to maximum wick height. Individual heaters vary but it will be some form of this procedure. Then check the tension on the spring so that when the tip-over switch will snap the wick to the bottom. If there is too much tension, unwind the tension one turn. Too little tension, wind it up a turn. ~~~~~~~~ 8. Ventilation Question: I know you are in the business of selling wicks and not answering random questions, but your page contained so much information I thought you may be able to help. I have purchased a Sengoku CTN-110 kerosene heater to heat the first floor (around 350 sq. ft.) of a townhouse, in roughly the center of this space is a fireplace I do not use (wood is expensive and the clean-up is a bear) but which is fully functional. If I placed the heater in front of the fireplace and opened the damper, would that give me the proper ventilation I needed to operate the heater safely, or would it be preferable to open a window? Answer: The open damper would provide the exhaust air to eliminate any very slight fumes during start-up and shut-down. But a chimney is for air exiting the house, not entering. Heater safety involving slightly opening a window is NOT for any other reason than bringing in fresh air to replace that consumed by the burning heater. In fact, a window should be cracked for exactly the same purpose when burning the fireplace! Modern, fully sealed houses like modular homes are required by code to have a separate, outside source of oxygen plumbed into a vent just for the heater or fireplace, for example. ~~~~~~ 9. Pinned wick installation problem. Question: I noticed that the knob to raise the wick for use was quite stiff. I then hit the anti-tip device & nothing happened, but it let me manually turn it off. I took it apart, checked everything & it was in working order. I found that when I place the wick in and over the metal column it rides against is when it gets "tight". Stan K in MD Answer: You have a pin hanging up. The

pins go through three sleeves. The inner sleeve has holes, the middle sleeve

has angled slots and the sleeve you cannot see, the most outside of the 3

sleeve, has holes for the pins. ~~~~~~~~ 11. Uneven burning, flame spikes, odor Question: My Prusman is emitting foul odors and my eyes are stinging inspite of having changed wick. I'm not sure if the issue is the wick placement or the catalytic converter allows too much air due to misalignment. The flame seems to move when I move the converter from side to side... Answer: You have an air

leak under the catalytic converter burner unit causing incomplete combustion,

the clue being the flame moves with the converter. 12. Flame dwindling in convection heater Queston: I'm finding that the wick is not keeping a good flame after the tank gets a little less than half full. Before that point I get a really high flame which I adjust with the knob. Answer: The usual cause

of fuel starvation is a little moisture in the wick. It can take as little as

a teaspoon of water to completely inhibit capillary action; a half teaspoon of

water can greatly inhibit capillary action. That moisture can occur through

simple condensation of the addition of emulsified water droplets when the

first container is poured from a tank after a night with high humidity. 13. Flame dwindling in radiant heater Question: You recommended a heater for me that I bought last winter and we absolutely love it. I'm having a slight problem though and wanted to see if you can help. The heater starts fine and has a nice blue flame initially but after running a few minutes, the glow begins to dwindle and the element starts turning black at the top. Do you think I need a new wick? It's a Heat Mate HMM-110. Jason. Answer: Dwindling flame is almost a certain indicator of water in the wick. The water is heavier than kerosene, clogs the capillary fibers, and not enough fuel can pass up the wick to sustain a burn. When the heater is not burning the wick can become saturated with fuel and start normally.

14. Stuck wick knob on Aladdin Blue Flame heater.

Question: The wick knob is frozen on the Aladdin Blue Flame heater I inherited from my grandmother. Help! Dan in Texas. Answer: The wick knob on an

Aladdin Blue Flame heater is actually the head of a thick bolt. That bolt

goes into the tank and screws into a nut mounted on one end of a lever. The

other end of the lever is close to the draft tube and has attached to it the

two arms that raise and lower the wick. That lever is a fulcrum, like a

child's swing (upside down), with the knob bolt at one end and the two lift

levers at the other end. The pivot point is close to the middle and is held in

place by the screw you can see between the knob and the tank. 18. Recommendations for a kerosene heater? Question: I'm looking to purchase a kerosene room heater. What are your top three recommendations for kerosene heater's? Answer: My top two are the CTN/HMN-110 radiant heater because it is more efficient and provides more uniform heating to use one or two radiant heaters spaced in different rooms (or widely separated) than one large convection heater.

Third place would be a large convection if you live in a

northern clime where temps can drop to zero for days on end, the C20000,

C20000A, CV-2230 = HMHc-2230 = KH-250 = Mega 230 = CV-23K, all the same

heater sold under different brand labels.

In really cold areas the best utility and even heat

possibilities are from using a radiant and/or a convection depending upon

the ambient temperature. Kerosene heaters must be operated at near maximum

output all the time, so the only way to cut down the heat is to use a

smaller heater, or conversely, add a second heater on really cold days. The

savings in fuel consumption alone offsets the additional smaller heater over

the course of a winter or two.

19. All-cotton wicks for modern catalytic burner heaters Question: Hello looking the an all cotton wick for my dura heat 2304 (pinned). Answer: There are no all-cotton pinned wicks. I make all-cotton wicks for many heaters but not pinned wicks. All pinned wicks are used in catalytic burner heaters. The heat generated at the top of the wick with a catalytic system consumes cotton very fast, and being a pinned wick there is no way to adjust the wick up to compensate for that wick height reduction. Burning diesel fuel, even with alcohol added, clogs the wick and ruins capillary action. Adding some alcohol helps raise the flame temperature and burns the tar deposits off the top of the wick but cannot completely compensate for the decreased capillary action caused by the oily component in diesel fuel. 20. Question: Is there anything I can do to remove the rust from inside the tank of a kerosun radiant 10 tank? There is a large amount of loose red rust in the tank and I am wondering if it worth my time to clean it out.

Answer: The rust came from leaving the tank with fuel in it. Any type of

fuel, clear or red dye, will permit water to enter the tank via humidity being

absorbed by the wick. Water is heavier than kerosene and separates, laying in

a layer at the bottom of the tank and causing rust. The fuel keeps the water

from evaporating. 21. Question: Hello Miles, you have so much great info! I have a question. I'd like a convection heater that is capable of occasionally heating a three season room (400 sq ft) in the winter.

Answer: The shape of the room and ceiling height makes a

big difference in heating requirements. For occasional heating and utilitarian

heating for emergencies it is generally better to use a radiant heater. The

radiant will produce heat that will heat YOU while also producing convection

heating that slowly heats up the air temp to acceptable levels. A long, narrow

room or one with high ceilings is particularly well suited to two radiant

heaters, one at each end, as when the room ambient temperature is comfortable

one of the heaters can be shut off. 22. Question: I have stored the heater in my basement unused for 6 or 7 years with 1/2 tank of fuel. The basement is fairly constant temperature and the storage room is dark, etc. We went to use the heater and it fired right up, ran fine, but then after a couple of uses it was hard to light.

Answer: The heater should be stored bone dry, meaning the

tank should be empty and the wick ''burned dry.'' Capillary action in a wick

works both directions; it wicks fuel up from the tank to support a flame but

it also wicks moisture from ambient humidity down into the tank when just

sitting still and not being used. Fuel stored in a heater also induces

condensation.

23. Question: I recently purchased a Butterfly 8700

sock wick stove from St. Paul Mercantile and am wondering if I can use a

fiberglass wick in it, and whether or not you can supply me with some to fit.

It looks like it might take a 6 1/2" flat width, 4 1/8" diameter, 8

1/2" high wick, although it looks like the 4 1/8" diameter measures more like

4 1/4" on the heater, so a 4 1/8" wick might be a little too small in diameter

by 1/8" or so. Do you know whether the 4 1/8" wick might work, and if so, is

it practical to use a fiberglass wick in a sock wick stove? I'm hoping to get

a little more life out of the wicks for this stove, as I will be using the

stove quite a bit.

For more information on burning diesel, and some all-cotton wicks,

click here.

|

| ||||