. . . .

World's Largest Selection of Wicks!

Wicks for virtually every heater, stove and lamp made since 1850

Lamp Repair & Projects

Electrocuted lamps - Identify this

problem first prior to any restoration

|

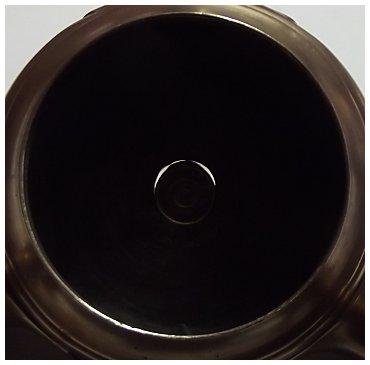

Center draft lamps which have been

electrocuted often have the center draft tubes cut down. That

is usually the end of any attempt to restore the lamp to burn

fuel as replacing the draft tube is costly and difficult. The

Rayo at near left still has an electric socket in the center

draft tube and cut down draft tube. The pot insert at right

has a cut down draft tube. |

Note center draft tube is

lower than the outer wick tube. Click on the photos to expand

them. |

Center draft tube has a

ragged top. |

STRESS CRACK REPAIR - SEALING THIN

SEAM LEAKS and PINHOLE LEAKS

Great information from R. Will Newman in Georgia

"I wanted to share something with you that I

have found very useful while working on these old lamps. As you

know it is quite common to find stress cracks in the brass fonts

and it is not always easy or feasible to solder them or use the

two part epoxy putty (which works well on perfection heater

fonts).

|

"I am in the heavy duty truck business and we frequently have

old rusty and leaky tanks sent to the local radiator shop to

be cleaned out and coated with a fuel tank sealer. The fuel

tank sealer is a thick red fluid ["Red Cote"] that you pour

into a tank and roll it around to cover all of the inside and

then pour out the excess. It will dry in an hour and then a

second coat is applied to "seal the deal". It is impervious

to diesel or gas and kerosene of course as well.

"I started with a well cracked brass font insert like are so

common and I simply tape up the cracks from the outside.

Stress cracks only now, not big gaping ones!!

|

|

"Pour in the sealant and turn the fount

on its side and roll it around to coat the inside. Care must be

taken to keep the sealant off of the center draft tube as much as

possible, but it is not critical as this sealant dries very thin

and dry not sticky.

"Pour the excess back into the container and then a couple of

hours later, do it all again. You can simply wipe the sealant

from the threads and acetone will also clean it. A gallon is

about $60 and you can buy it on line. That much is a lifetime

supply for a lamp guy!" |

|

[Remove all of the wick raising

parts you can remove, especially wick sleeves. Remember, the

lamp fonts were made first then the wick raising parts installed.

Hence, all of the parts inside the tank CAN BE removed from the

font. Note also that the tank MUST BE clean and dry.

The tank can be cleaned with a hot soak in citric acid bath,

rinsed with gasoline and then cleaned with acetone, and with any

method used must then be thoroughly air dried PRIOR TO adding the

Red Cote to the inside of the tank. Miles] |

|

It is not uncommon to find pinholes in the base of

the fuel tank on century-old fuel fonts. First empty the font. Pick at the holes with a stout sewing needle to clean

debris from the holes, remove any oil from the metal with acetone on

Q-Tips, and

apply a thin layer of J-B KwikWeld epoxy. In 10 minutes

the leak is sealed. J-B KwikWeld can also be used to seal

stress

cracks in drop-in fonts IF the stress crack is not too large

and pressed inward so the finished result does not result in a

wider font. |

|

UPDATED SEPTEMBER 28, 2023 - Small crack or

seam sealing

|

RED COTE and POR-15 are permanent repairs

and cannot be reversed. For museum quality lamps that can

lower the value of the lamp, if that is a concern.

If you want a simple, virtually invisible, museum quality

(reversible) repair, use good old clear shellac. It seals fine

cracks 100% and is impervious to kerosene. An alcohol rinse

will remove every trace of the shellac. ("Super glue" works

the same as shellac for those who may use alcohol in their

fuel to absorb moisture.)

Note that shellac is thin and cannot fill

and seal wide cracks and splits such as stress cracks often

found in drop-in fonts. Thin splits or seams such as on the

fonts on student lamps can often be sealed with a simple

coating of shellac carefully applied only to the seam or

crack. Note that the insert font on student lamps is

inverted! If there is a tiny crack in a seam on the BOTTOM of

the font there is an air leak and the proper vacuum action to

only allow a little fuel out of the bottom of the font is

broken, the entire font will leak out. |

Click on the image to enlarge

The actual bottom of the

font is on TOP, inverted, in the photo above. When inserted

into the font holder the

bottom of the font, which is where the fuel is filled, is

placed DOWN in the font holder. |

======

EASY SOLDERING REPAIR

Sometimes it is necessary to effect simple lamp repairs just to

get an old lamp back into working condition. The first

example will be a Lampe Florentine.

|

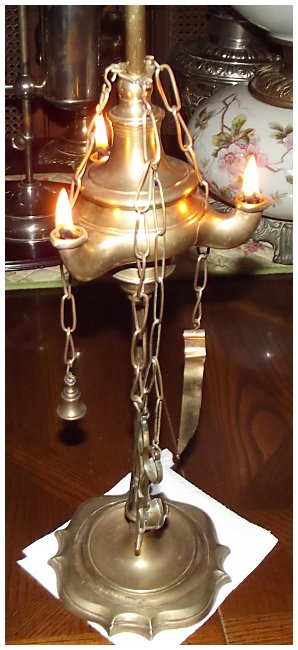

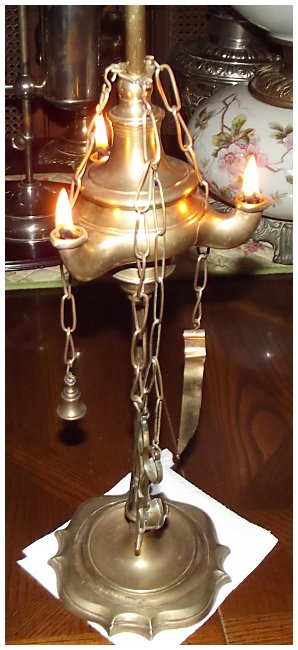

At right is a 3-wick Lampe Florentine.

These lamps were made and used for most of the 1800's in the

Pyrenees Mountains in both France and Spain. They were

used concurrently with Argand lamps, mostly in rural areas.

The fuel they require is almost any heavy oil such as olive

oil, canola oil, sunflower or walnut oil. The wicks are

1/4'' diameter cotton wicks, but many vegetable fibers can be

twisted together and used. Light outout is not great but

is sufficient for area lighting. The very simplicity of

wicks and versatility of fuel requirements meant the Lampe

Florentine could be used without any outside supplies needed -

a distinct advantage in very remote villages in the 1800's. |

|

The photo above shows the missing post in the

font. Not only would fuel pour out but the font itself is

not stable. I had to use brass, of course, to make a new

post. Measurements showed that a .30-06 cartridge case would

fit fine. The case was trimmed right at the shoulder using a

Dremel tool with tiny cutoff wheel. The photo above right

shows there was still too much space between the cartridge case

and the font.

I used an old Lyman 310 Tong Tool and a .44

Special expander to put a bell/flare on the top of the case.

The second photo above shows there is still room around the

cartridge case for solder, and the 3rd photo shows the bell or

flare fits perfectly into the bottom of the font. The photo above,

far right, shows the cartridge case with the head trimmed off and

soldered into the font. The case has enough height above the

font so fuel can be poured in without spilling and the case fits

tightly enough to the rod to keep the font stable.

|

The repairs worked! At right is the Lamp

Florentine burning brightly for perhaps the first time in a

century. |

|

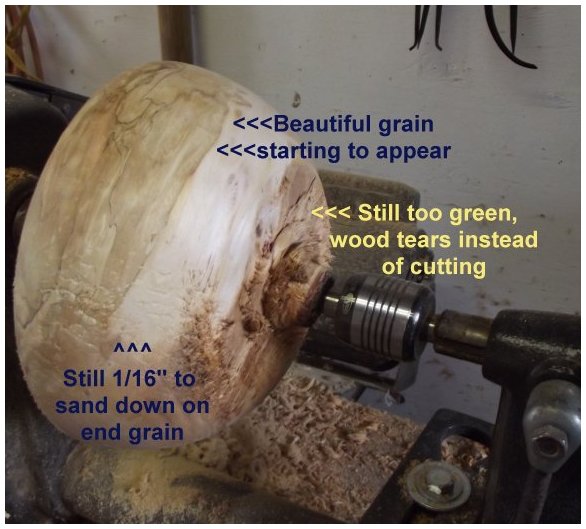

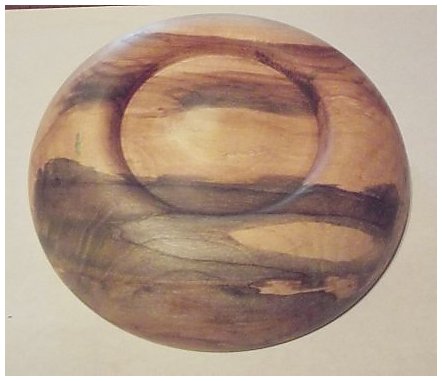

Wooden stands and wood lathe projects

Many store lamps have a wick lift rod which

extends beneath the drip cup. An elevated wood stand solves

that problem when using a store lamp as a table lamp. Other

types of lamps can also benefit from a wooden stand. If you

have a wood lathe or have a friend with one, these projects are

simple elementary wood turning.

I made the base above for a 30''' Central

Vulcan lamp because a hot-rod lamp like a Vulcan projects a lot of

heat downward through the draft tube. That can be hard on a

nice wooden table, but a lamp stand solves that problem.

|

The two lamp stands at right were trials to

see what they would look like. The Rochester store

lamp on the left is sitting on a very ugly stand. That

one was discarded.

The Imperial lamp on the right has a thick

post-type font. I made that stand simply by holding a

chunk of cedar firewood to a belt sander and grinding it

down. It looks pretty good, not as pretty as a

lathe-turned base but not bad. |

|

Wick sleeve cleaners

|

|

These wick sleeve cleaners were lathe

turned from broken hardwood tool handles and can be used to

clean and polish the inside of wick sleeves so the sleeves

slide up and down the draft tube smoothly. |

Soldering Stress Cracks in oil pots

Back to top of page

|

Wicks for kerosene space heaters,

click here.

Lamp fuel caps - click here

Lamp Wicks:

Center Draft Wicks - Wicks

available only from this Wick Shop.

#0L,

#1B,

#1M,

#1R,

#2L,

#2R,

#2 P&A,

#2B,

#3L.

Flat lamp wicks

and

Kosmos Lamp Wicks

Aladdin Lamp Wicks

& parts

Lamp Chimneys:

Center Draft Lamp

chimneys in borosilicate glass

from Junior "Tiny" to Mammoth lamps.

#0M,

Rayo

Jr.,

2

1/2",

2 5/8",

2

15/16",

3 1/8",

4",

4

1/2"

Standard glass lamp chimneys

& Kosmos chimneys

Globe Vulcan (Central Vulcan) Chimneys -

18''',

24''' &

30'''

Fabulous "Sans Rival"

borosilicate chimney for 14''' Kosmos lamps

Student Lamp Sans Rival Chimney with

1 7/8" fitter!!!

Angle

Lamp chimneys

Sonnenbrenner Lamp Chimneys

Lamp Chimneys

- Dimension of

nominal base diameter by make, model and "line".

Information on lamps:

Aladdin Lamp History

Aladdin Lamp Wicks & Chimneys,

Aladdin - Exploded burner views

Beginning Lamp

Restoration

Center Draft Kerosene Lamps

(Photos, information and history, etc)

Center Draft

Lamp manufacturers and brand names

Kosmos-Brenner

lamps

Photos of

restored center draft lamps

Victorian Era

Student Lamps

USE, CARE and WICKING of CENTER DRAFT LAMPS

Early American Metal Font & Specialty Lamps

Flame Spreaders and

"Smoke

Consumers"

from Alex

Marrack

- Vulcan, Imperial, Veritas,

Belgian, Hinks, Messenger's, Young's Court, etc.

Articles by Alex Marrack:

Home Page

Site Index

Site Index for all things Perfection

Links to web sites for parts,

information and restoration.

Kindler Wicking For Oil Stoves & Ranges

Kerosene Heaters

Alphabetical list of most kerosene heaters and the proper wick,

& cart checkout.

List by wick number and the heaters that fit them. (A

helpful guide for buying on eBay)

Back to top of page

|