|

Top

WICKS TO FIT THE HEATERS LISTED

BELOW - AND MORE!

Unique Specialty wicks

for

19th Century lamps

|

. . . .

World's Largest Selection of Wicks!

Wicks for virtually every heater, stove and lamp made since 1850

MAINTENANCE - KEROSENE

APPLIANCES

Preparing your

kerosene heater for summer storage is a regular maintenance routine

that absolutely should be done every year, thus ensuring the heater is

in perfect condition for use. And the same maintenance items

should be checked to ensure the heater ready for winter use.

Properly cared for, your heater will last for many decades. Some

Perfection heaters are used every winter after a century of use...with

proper care for storage during the summer.

It isn't hard or

complicated to properly prepare a heater

properly.

Regular maintenance

of kerosene appliances involves care

of the wick, the wick raising assembly, plus the main

body of the appliance itself.

Wick raising (and lowering)

assembly:

I have seen fiberglass

wicks with so much tar buildup on top that they cannot be

withdrawn into the wick raising assembly, ratchets and

levers so dirty they could not be moved, even wicks

rusted to the center support column! All of those

are the fault of the user, not the heater

or stove. The wick raising assembly can be carefully

scraped and then cleaned with an old toothbrush and

kerosene and wiped dry. "Tri-Flow" (or silicone)

penetrating lubricant can then be sprayed on all moving

parts; when it dries it leaves a film of Teflon and

silicone, and that will keep it working for well for

another year. If there is rust present on the

central post assembly because someone stored the unit wet

(with fuel in the tank) and water condensed and was able

to get to the carbon steel pillar around which the wick

fits, then wire brush the rusted area and sand it smooth

with fine grit emery paper.

The area around the wick

gap (below) often gets tar or carbon deposits, which can

be cleaned off easily when cool and therefore

brittle.

|

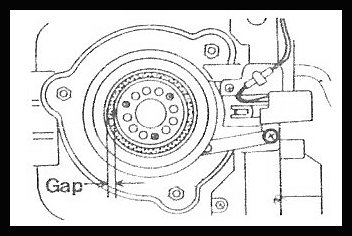

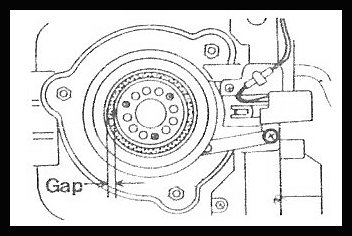

Wick raising assembly at left, igniter with

electric wire leads shown on right side of

illustration. Trace those wires and clean

all the contact points all the way to the battery

terminals.

|

The Electric Ignition

system

Virtually all

kerosene heaters use 2 batteries (C or D size) to provide

the electricity to heat the igniter to light the

heater. The contact points of this system can

corrode, so they do need periodic attention. The

best electrical contact cleaner I have found is Tronic

Kleen Plus Lube, available from Radio Shack

stores.

Remove the

batteries, spray with the "Tronic Kleen Plus Lube," and

wipe dry. Trace the wires from the battery and you

should find a long, flexible copper contact strip which

is touched by the igniter contact when you move the

ignition lever. That copper strip can become

corroded, and then the lighting system will not

work. Light sanding with fine grit emery cloth will

restore the copper surface, then spray with Tronic Kleen

Plus Lube, wipe dry, and it will be protected against

corrosion throughout the heating season.

Most igniters

resemble a flashlight bulb with the glass removed and a

tiny resistance heating coil on the top. That

heating coil can become corroded, clogged with debris, or

break. The igniter can be checked for proper

operation by replacing the batteries, moving the igniter

operating lever, then observing if the heating coil glows

red hot. For maintenance, remove the igniter, spray into

the contact receptacle with Tronic Kleen Plus Lube, then

replace the igniter. If the igniter is damaged, it

should be replaced with the correct

igniter - there are four different types of

igniters!

|

The photo at

left shows an Everglow P-E12 fuel tank with

attached wick raising system and the electric

ignition system on the right. The lever is

moved to the right, which moves the igniter to

the left to contact a copper strip contact point

and then the raised wick. I bought the heater as

unused on eBay in late August, 2006. The

ignition system did not work, which was probably

the reason it was sold. A continuity tester

showed good contacts. The batteries produced 3.2

volts at full amperage...and didn't work.

The batteries were shorting themselves out!

I replaced the batteries and it works just

fine. Click photo to enlarge.

|

When the kerosene

heater is prepared for storage for the summer, remove the

batteries and clean all the electrical contact

points. Before use in late autumn, the electric

starting system should be in good condition, awaiting

only the installation of new batteries.

The

Appliance Body

Virtually all kerosene

heaters and stoves are made of steel, either painted or

enameled for a pleasant appearance and rust

prevention. Most modern heaters have a baked enamel

finish. "Perfection" heaters were painted, and as a

result will rust easily...they should be cleaned and

polished twice a year. When the appliance is being

prepared for storage, it should be burned dry

(not Perfection heaters!), then completely

disassembled. The body of the unit, including the

stainless steel reflectors on radiant heaters and

stainless steel grillwork on convection heaters, should

be cleaned and polished with a good grade of auto

polish/cleaner: my favorite is "Meguiar's Cleaner/Wax,"

which the maker claims is America's top selling

cleaner/wax. It's cheap, and it works. Don't forget to

polish the inside of the metal cabinets, as they

are often unpainted and rust easily if not protected with

metal polish. The auto polish will seal the pores

of the paint and steel, greatly reducing the chance for

rusting.

This

heater has been used to heat my shop for 10 years,

and is as pretty as when new.

If rust is present. First, if the rust is not

too extensive or deep, a small brass brush is used to

remove all rust scale and debris. Be sure to remove

any enamel, paint or chrome from the edges of the rusted

area. The area can then be sanded to remove high

spots and "feather" the edge of surrounding

paint.

If the rust is

severe. From George C, a reader.

1/15/08. "Well sir I have been using this product

called Evapo-rust for over two years at work to clean

gage pins. I took the whole wick adjuster and safety

shutoff along with the igniter and soaked over night. it

works like a new one and trips just great. If it had not

been for this stuff would not have been able to salvage

the heater." http://www.evapo-rust.com

To protect the

areas you have cleaned, they must be neutralized to

prevent the oxidation from eating right through the

metal. "Ospho" (phosphoric acid) neutralizes

rust, and is available in many hardware stores. Use

a small, cheap paintbrush and carefully apply a thin

coating Ospho to the cleaned rusted area. Do not

spill any Ospho on painted surfaces or they will be

stained! Ospho needs a temperature of about 70 F to

properly dry. You will know the Ospho has worked

and is "cured" when the rust turns very dark and is no

longer tacky to touch. That area should not rust again,

particularly after the application of a good coat of

paint. Thanks, Tom!

Paint:

A good quality engine block paint rated at 1200 F will

normally work very well, but color matching is

difficult. Tom Poserina found that Chrysler 300

White touch-up paint from Wal Mart was a perfect match

for the paint on the fuel tank of his Omni 105

"E".

Note from a

reader: 1/26/2012

I thought I'd also

mention I found an almost identical match to the

off-white color Toyotomi used on their Radiant

series. I went to one of our local O'Reilly stores

(national chain of auto part stores) and found a can of

Dupli-Color's "Perfect Match" series of automotive

sprays; their "Wimbledon White" color for Ford vehicles

is a dead ringer for Kero Sun's. It was actually cheaper

to buy a spray-can than the little touch-up paint tube,

so I used the old technique of simply spraying enough

onto some cardboard until it pools and used a broken

toothpick to apply it to the chipped areas of the

heater. Just thought you might be interested in

passing it on. Thanks again for all the hard work

you do maintaining your website. It shows that you

care about the products you sell!

Travis G.

Flame_Spikes

|

|

The two inner

cylinders of the catalytic converter are spaced so

that one fits inside the wick and one fits outside,

so the wick is between the two perforated

cylinders. The wick bring fuel to the base of

the cylinders through capillary action. When

the catalytic converter is up to operating

temperature, the fuel vapor is combined with oxygen

flowing through the perforations. The flame

is then between the cylinders,

not from the wick - the rings

convert fuel vapor to clean,

virtually odor-free flame heat.

|

The two steel

cylinders of the catalytic converter are soft and easily

damaged. Even if made from hardened steel, the heat

produced by the stove in use would quickly anneal the

cylinders and make them soft. Normal bouncing

during transit, storage or use can result in nicks or an

uneven bottom edge of the converter rings. If

the bottom edge of the burner rings is not perfectly

flat, an air leak and cause extra oxygen to enter the

space between the cylinders, upsetting the delicate

air/fuel mixture and causing an flame spike. And

that air spike will cause sooting if it is high enough to

impact the bottom of a pot or pan.

An "flame spike" can be caused by

too high a wick as well as an air leak. To

determine the problem, grab the wire handle (see photo

above) on the catalytic converter and move it slowly from

side to side while watching the flame. If the

flame spike does not move, the cause is a wick too high

at that location - the wick is not level.

Remove the wick and reinstall it so it is level on

top.

If the flame

spike moves with the catalytic converter, the cause

of the flame spike is an air leak from the base of the

burner. That is relatively easy to fix. Place

a new sheet of sandpaper of 120 to 150 grit on a flat

surface, like a Formica countertop. Place the

catalytic converter base down on the sandpaper close to

you and hold an edge of the sandpaper down against the

countertop. Then gently stroke the catalytic

converter away from you, one stroke only!, while keeping

the catalytic converter as flat as possible. Lift

the catalytic converter and return it to the near edge,

then make another stroke. Now examine the bottom

edge of each cylinder. The shiny spots were high

spots that were sanded down. The dull places are

too low and will cause an air leak. Repeat the

sanding strokes until both cylinders are shiny rings all

the way around. Bingo, no air

leak.

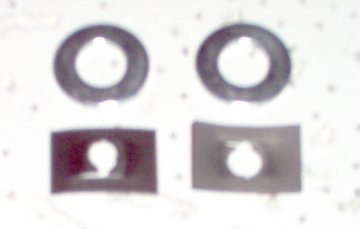

Corona 22-DK wick sleeves.

|

Corona 23DK wick

sleeve. The Corona 22DK was a transition model using an

unpinned wick and a pinned wick sleeve. That pinned wick

sleeve was very fragile as the pins could easily break off.

The sleeve can be drilled where the pins were located and the

heater will then work using pinned wick #3B for the 23DK, or I

have new 23DK wick sleeves.

Click

here. |

Corona 22-DK wick sleeve - no longer available. |

Corona 23DK wick sleeve |

FIXING A LOOSE CARRY HANDLE

ON A CONVECTION HEATER

Many, if not most

convection heaters have a carry handle in the shape of a

"U" which attaches to the heater by simply slipping into

holes on each side of the tower assembly. The problem is

that one side of the carry handle can slip out and the

heater can be dropped. This problem is almost

universal...and extremely easy to fix. Remove the

top safety grill, then the top plate on the heater.

Now you can look down into the heater and see the ends of

the carry handle protruding through the metal sides of

the heater. Slide a 5/16" washer over each end,

then a 1/4" "Kwik-Clip" over each end and slide it back

as far as you can, and the carry handle will not be able

to come loose again. Some carry handles are less

than 1/4" diameter chromed rod and would require a

smaller "Kwik-Clip," and they are available in just about

any small diameter.

|

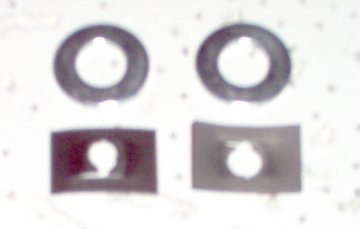

The photo at left shows 1/4" "Kwik-Clips"

and 5/16" washers. The "Kwik-Clips"(also called ''Speed Nuts") are part

#08236 00661 or 08236 00672 at True Value Hardware stores, and

cost all of 15 cents each. The 5/16"

washers are 5 cents each. For 40 cents you

can solve an aggravating problem!

|

You're

done....

The unit is now cleaned

and polished, the mechanical wick raising assembly

cleaned and lubed as is the electric starting system, and

the appliance body polished and thus protected against

stains and rust. The fuel tank is empty, so water vapor

will not condense in it and cause rusting. You removed

the igniter batteries when you removed the cabinet body,

so no galvanic corrosion should take place in storage.

And you have examined the wick, and if replacement is

needed, now is the time to at least order the proper

wick. Now the unit may be safely stored -- covered!

-- in a dry area, and you can be certain your kerosene

heater will be ready for use just as soon as you need it

again.

Is this

all really important?

Yes. I have had to

practically rebuild convection heaters from scratch for

friends because they were simply put into a damp

outbuilding after the last use. They were rusty and a

real mess, and there is no excuse for it! A few

years ago I was given a Toyotomi RCA-87 radiant heater

for free. It had been put away wet -- in a barn

loft, under hay bales. It was rusty and dented, the

electrical starter system so corroded it could not be

fixed, with mouse nests in the wick raising assembly

area. I was able to make it work again, but it wasn't

worth the effort...a $200 heater ruined for lack of a

half hour of maintenance work!

If you follow the

guidelines above for regular maintenance before storing

your kerosene appliances, they will keep in pristine

condition and be ready for use within 20 minutes of when

you need them -- just fill with fuel and install the

batteries.

QUESTION FROM A READER:

Thanks for the wicks

and igniter you sent. They're great. I have one heater that despite

using contact cleaner on the ignition system, I can't seem to get it

to work. Is there a way that I can remove the entire system from the

heater in order to more closely inspect it without damaging it beyond

repair. And do you sell anything I could use to clean the fuel tanks?

They're not terribly dirty, but as long as I'm this far into it, I may

as well do it as best I can. Thanks again, Miles! Jeff in

Dry Fork, VA

ANSWER:

You need an inexpensive electrical tester for the

ignition system. And you will probably need a third hand to help you

because you need two hands to hold the leads and someone else to push

down the igniter button when you get to that point.

Without batteries installed, use the continuity tester for the + and -

on the battery box, then each wire up to the connector. Then test the

continuity through the switch while someone engages the igniter to

full on. That will isolate the bad connection. Then you can use 600

grit emery to clean the contact. Reinstall the batteries and check

for voltage at the battery box, at the igniter itself as well as at

the first connection. It should read very close to 3 volts DC. Often

the bad contact is right in the center of the plug socket itself - the

positive wire. Insert a pencil-style ink eraser into the plug-in and

twist it to clean that contact. Go gently and do not bend the folded

copper contact at the bottom of the receptacle down to far or it will

not make contact with the base of the igniter. Run your final voltage

check from the center probe in the receptacle while holding the

negative contact on the outside of the socket while someone engages

the igniter.

The fuel tanks are not difficult to clean. Kerosene is not called

"paraffin" in Europe without a reason: kerosene precipitates paraffin

and other waxes. The waxes, being tacky, almost attract and hold all

kinds of detritus. Nothing dissolves those waxes, but they generally

melt at less than 180 degrees F. Boil water in a tea kettle until it

whistles at 212 F, then pour into the tank. Replace the cap, swish

around quickly, then pour out. All kinds of melted stuff will pour

out with the almost-boiling water. Repeat several times. Finally, to

remove residual water, pour in at least a cup of 91%+ alcohol, swish

around, and pour out. Air dry with the cap off before use.

Back to top of page

|

Home Page

Site Index

Kerosene Heater Wicks:

Kerosene Heaters

Lamps

Home Page

Site Index

Photo Album

Photos of

Wicks

Mail Order

Form

Back to top of page

Kerosene Stoves, Lanterns and Ovens

Kerosene Stoves -

Recommendations on different models

New!

Kerosene

Stove Maintenance and Storage

Butterfly A-822, 22 wick, all-aluminum

premium stove. New!

Butterfly #2487, 16 wick stove. Butterfly #2412 Pressure

Stove;

instructions for virtually any pressure stove.

Butterfly #2418

Double Burner Stove;

good with any gravity flow stove.

Butterfly #2421

Oven for Kerosene Stoves

Butterfly #2641, 10 Wick Stove

-

the least expensive emergency stove.

Butterfly #2698 Cook Stove -

THE Best Heavy Duty Cook Stove. Butterfly

#828R Pressure Lantern;

same for most pressure lanterns.

|